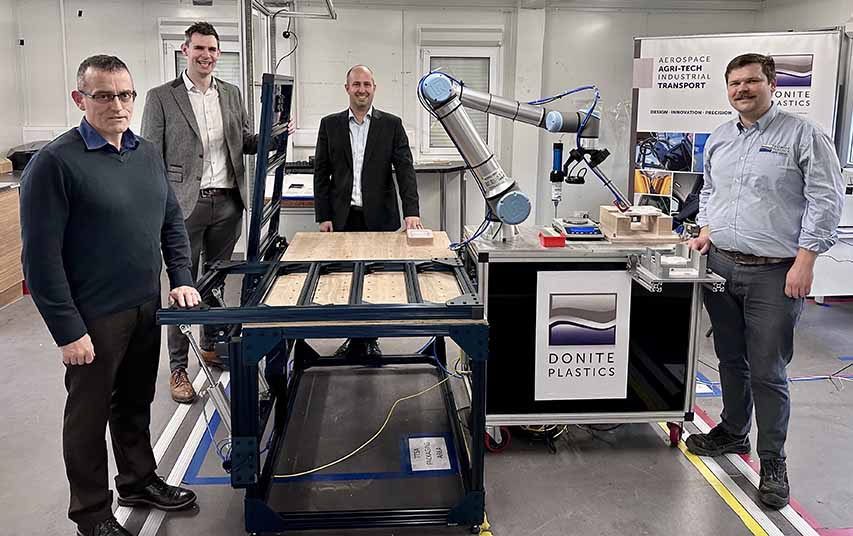

Donite Plastics Delivers on Innovative Aerospace Project

A Saintfield company has concluded a project to develop an automated assembly process for aircraft seating.

Ireland’s leading industrial thermoforming company, Donite Plastics, in partnership with Northern Ireland Technology Centre (NITC) at Queen’s University, Belfast, has concluded an innovative project that will see the introduction of smart technology into the aircraft interiors assembly process and the creation of up to eight jobs later this year at the Saintfield-based company.

Donite Plastics has been supporting customers in the aerospace sector for several years and through this project, awarded by the National Aerospace Technology Exploitation Programme (NATEP).

It is co-funded by Innovate UK and the Aerospace Technology Institute (ATI), has developed a robotic automated assembly cell for advanced Thermoformed Twin Skin Panels (TTSP) for aircraft seating systems.

Aircraft interiors, and in particular aircraft seating, incorporates many variations of access panels, with the traditional designs generally assembled using conventional assembly techniques.

The technology that has been developed will create a human and machine collaborative environment that will see improved efficiency for both Donite Plastics and its aerospace customers, through a reduction in assembly time and increased part quality.

The introduction of bonded twin skin vacuum formed panels, where appropriate, also has the potential to increase sustainability across the sector through significant cumulative weight savings, with the company’s latest development producing lightweight panels and components with up to 39% weight reduction and 89% part reduction per panel.

These technological advancements will enable Donite Plastics to further its offering to its aerospace customers and make a greater impact on the thriving sector.

Patrick Knight, Engineering and Research and Development Manager at Donite Plastics spoke about the project and said: “As a result of our participation in this programme, we have been able to build our knowledge and expertise, and further our value adding to existing customers.

‘These customers are not just those within the aerospace sector, but in additional sectors.

“It has also helped us to engage with potential clients and trial new innovative processes that will expand our capabilities and help meet our growth aspirations going forward.

“With an investment of £500k, which included automated thermoforming and CNC trimming equipment, this R&D project will help us to develop these capabilities going forward and meet the everchanging requirements of our customers.

“Later this year, we will also be commencing a recruitment drive to accommodate the additional workload to the company as a result of the project.”

The new technology developed by Donite Plastics throughout the project will be utilised by one of the company’s largest customers, Thompson Aero Seating.

Aaron Robinson, Head of Design at the company said: “This was an excellent project, which has proved beneficial to Thompson Aero Seating. Seeing the development of the new technology and the end result, has been very rewarding.”

Rory Collins from the Northern Ireland Technology Centre, which is now part of the Belfast Region City Deal-funded £100m Advanced Manufacturing Innovation Centre being delivered by Queen’s with industry, government and academics partners, also commented.

He said: “Throughout this successful and innovative programme, our staff have been able to further their knowledge and capability in the area of automation and robotics.

“That will contribute to the success of our projects within AMIC, which is set to reinvigorate Northern Ireland’s industrial potential and address the future technology and skills challenges faced by the region’s manufacturing sector. We wish to thank the team at Donite Plastics for their hard work and dedication throughout the project.”

Steven Stanley, NATEP Technology Manager said, “We are delighted to conclude the project with Donite Plastics and NITC and see the progress that has been made since its inception.

“Both organisations have used their extensive experience to develop a pioneering product and process, and we look forward to seeing how it develops going forward.”

Donite Plastics is committed to continuous improvement and through the NATEP programme, has been able to improve its processes for the long-term benefit of the company and its customer base.

It plays a pivotal role in the growth of the UK’s aerospace sector, and as a pioneer of lightweight technology, has the ability to produce thermoformed parts and complex assemblies for leading aerospace manufacturing companies across the globe.

The new lightweight technology, developed as a result of the programme, will prove instrumental in reducing the weight in complex assemblies, and therefore assist customers with their sustainability practices.

The culmination of this project comes at a very exciting time for Donite Plastics as it looks toward further expansion in 2024 and a greater improvement of its processes, whilst remaining a pioneer in the thermoforming sector in Ireland, the UK and beyond.